HDPE Pipe Fittings

PE pipe and fittings are free from corrosion in all ground conditions and its flexibility allows it to withstand ground movements. No protective layers or finishes are required.

PE systems can be fusion welded so there is no risk of leaking from joint distortion. PE pipe is available in coils in long lengths. PE pipe is a common choice for trenchless technology.

PE fittings complete the PE pipe package using electrofusion and butt welding technology for jointing.

Introduction

PE pipe and fittings are free from corrosion in all ground conditions and its flexibility allows it to withstand ground movements. No protective layers or finishes are required.

PE systems can be fusion welded so there is no risk of leaking from joint distortion. PE pipe is available in coils in long lengths. PE pipe is a common choice for trenchless technology.

PE fittings complete the PE pipe package using electrofusion and butt welding technology for jointing.

Advantages

1. Long working life. Minimum 50 years life under normal conditions.

2. Hygiene. PE pipe are nontoxic, without the composition of heavy metal additives. No scale, not breeding germ, no second pollution to the potable water.

3. High resistance to attack from various types of chemicals. No electrochemical corrosion.

4. Smooth internal surface. Extremely low friction coefficient. Improved capability for media to pass through. Excellent abrasive resistance.

5. Good flexibility, high resistance to impact. Resistance to earthquake and twisting.

6. Light weight, easy to transport, convenient installation.

7. Unique electro fusion welding and butt welding make the joints stronger than the material, to guarantee a safe and reliable joint.

8. Simple welding technique, convenient installation. Total cost is low for the installation.

9.Butt weld elbow are produced in black, black with blue stripes and blue etc.

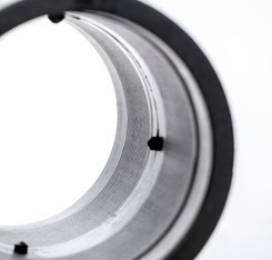

Butt Fusion Fitting Features

1. It is used for connecting pipes of all specification which have the same materials and the same SDR system

2. It possesses reliable connectivity, high interface strength, good airtight performance, and stable welding performance.

3. It is easily welded and operated, and conveniently used.

4. It is not easily affected by changes in environment temperature or human factors.

5. The hidden spiral heating wires buried inside can effectively resist oxidation and rust corrosion, ensuring stable welding performance.

6. The cost of equipment investment and maintenance is low.

7.Used in gas ,water, oil filed, mine, chemical industry, irrigation and drainage system.

Pipe fitting details

FAQ

1. Can I get free samples?

A: Yes, we can provide you the free samples, but you need to bear their own delivery costs.

2. Can I request to change the form of packaging and transportation?

A: Yes, We can change the form of the packaging and transportation according to your request, but you have to bear their own costs incurred during this period and the spreads.

3. Can I request to advance the shipment?

A: It should be depends on whether there is sufficient inventory in our warehouse.

4. Can I have my own Logo on the product?

A: Yes, you can send us your drawing and we can make your logo, but you have to bear their own the cost.

5. Can you produce the products according to my own drawings?

A: Yes, we can produce the products according to your drawings that will be most satisfy you.

6. Which price terms could accepted?

A: FOB,CIF all acceptable.

INQUIRY

CATEGORIES

LATEST NEWS

CONTACT US

Contact: Lori

Phone: +8618269993953

E-mail: lori@porainarpipe.com

Whatsapp:+8618269993953

Add: Room 1006,Building 15,zone B2,Bishui Yayuan,Liulin road,Yingzhou District,Anhui Province.